The know-how of today to prepare for the future.

At Natural Granen, we installed a new production unit delivering high-quality products. The company’s third generation, led by Stephan Descheemaecker, understands more than ever that pigeon racing still has a future.

That is stressed by all of Natural’s clients across the globe. The experience that the company gained over the past 80 years and its know-how on the sport have encouraged the Natural company to continue to invest in our sport. A modern new factory, or rather an entirely new production process, has been initiated in Schoten in 2016. The goal is to better meet the demands and the needs of pigeon fanciers across more than 50 countries who would like to practice pigeon racing in a modern way, whether as a professional or a hobby player.

This cleaner thoroughly cleans the grains and seeds upon delivery and removes dust particles. The state-of-the-art machine can thoroughly clean and dust twenty tons per hour.

In this secondary cleaner the grain mixtures and seeds are thoroughly cleaned and dusted a second time, just before they are being packaged.

In October 2015 Natural started working on an entirely new production unit in its pigeon feed factory in Schoten and we are proud to inform you that the updated unit is operational since early May 2016, producing ready for-use mixtures fully automatically.

You have probably seen the new packaging system with sewn bags. However, it does not stop there. The most important improvements have been made to the mixtures themselves. Thanks to the new production unit all mixtures are now being manufactured dust-free and they are precisely and evenly mixed, in accordance with the production instructions.

These are two of a total of five silo scales which weigh the individual ingredients of each mixture, as stipulated by the production instructions. It allows us to measure out each mixture with extreme precision.

The brushing machines give the grains a shiny appearance.

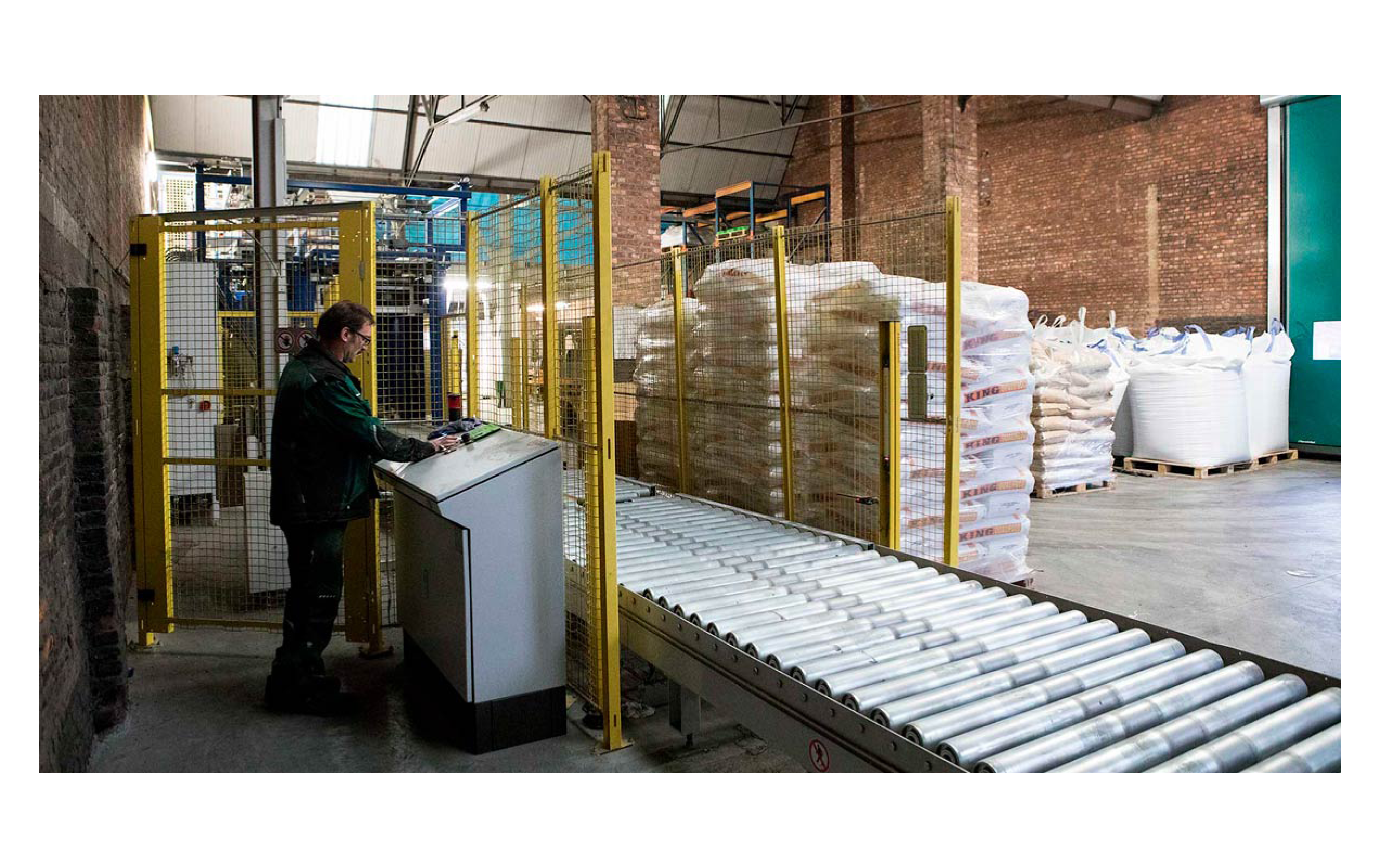

We also invested in modified silos, cleaners and secondary cleaners, new brushing machines, new mixers, new silo scales, a new bagging and packaging machine, a new palletiser and a new stretch film machine. Needless to say these are all computer-controlled installations equipped with the latest technologies.

Natural strongly believes in a modern pigeon sport and in the continued existence of our hobby.

The new mixers ensure a homogeneous composition of each mixture, making sure each mixture has a balanced amount of different grains and seeds.

This 30-meter long bagging and packaging machine performs each step in the packaging process fully automatically: labelling, filling and sealing the bags, as well as palletising.

That is why we continue to provide quality products at an affordable price, combined with our extensive expertise and with targeted advice tailored to the customers’ needs.

We included a few pictures which should give you an idea of our updated production unit, which will not only benefit your wallet but will also benefit your pigeons’ digestive system.

We hope we can continue to win your confidence.